-

FIRE PROTECTION

- FIREFLEX® DUAL

Combined Automatic Sprinkler and Clean Agent

FireFlex® DUAL is a combined automatic sprinkler and clean agent fire integrated suppression system. Designed with user-friendly features, the units are easy to install and maintain.

Benefits of the FireFlex DUAL Units

The FireFlex® DUAL system uses FK-5-1-12 Fire Protection Fluid combined with a Viking Preaction System. This clean extinguishing agent is based on sustainable technology and is the only chemical agent currently available that not only meets current regulations.

- Simple and quick installation thereby reducing costs

- Compact factory assembled and tested systems

- Lockable doors to avoid unauthorized handling

- Clean agent safe for occupants

- Environmentally safe long-term solution

- Available in multiple sizes

- Serial number for easy reference

- FM Approved as an assembled unit

- UL/ULC Listed as an assembled unit

- Seismic type contruction, up to a 601 lbs cylinder, 36'' or 46'' cabinet.

The FireFlex® DUAL Cabinet

Factory assembly of the FireFlex® DUAL cabinets ensures that all components have been carefully integrated. All systems are fully programmed and tested at the factory which facilitates the onsite installation and commissioning process.

The FireFlex® DUAL cabinets are of the freestanding type and are made of robust 14 gauge steel with a corrosion resistant fire red paint finish, polyester powder-coated and oven-baked on a phosphate base. Cabinets are also provided with two locked frontal doors that are removable, reducing space requirements for ease of installation and maintenance. Furthermore, all doors are provided with a neoprene gasket to reduce vibrations.

Technical details:

- FM Approved for engineered systems

- cULus Listed for engineered systems

- Compact layout saves floor space

- Fully tested and programmed at the factory

- Unique serial number on every unit

- User-friendly owner's manual with every unit

- Simplified operation and maintenance

- Factory built under ISO-9001 conditions

Construction Options For a Better Flexibility

Remote-controlled Option

The remote-controlled option provides a junction box where all supervisory and control devices, are prewired to a set of terminals for field wiring to a releasing control panel to be provided by others. The system’s electric actuator must be compatible and listed with the releasing control panel.

Seismic Construction Option

- The FireFlex® DUAL seismic construction option is available with or without panel up to 601 lbs cylinder on the 36” and 46” cabinet.

- The seismic construction option is tested and qualified in accordance with:

- International Building Code, 2006-2009 Edition

- California Building Code, 2013 Edition

- ICC-ES AC-156, 2010 Edition

Multiple Models and Available Configurations

Our adaptability, in order to better meet our customers' needs, is our main priority.

Units Dimensions

| DIMENSIONS | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 36" | 35 3/4" | 25" | 77" | 37 3/4" | 39 3/4" | 15" |

| 46" | 46" | 25" | 77" | 48" | 50" | 15" |

| 52" | 52" | 31" | 81" | 54" | 56" | 21" |

Note : Dimensions and actual size may vary depending on options and configuration selected, please refer to data sheets for exact dimensions.

Dimensions of Remote-Controlled and Self-Contained Units

What FireFlex DUAL units are made of?

FireFlex systems are made of industry-recognized components. We’re proud to work with these amazing partners.

Integrated Releasing Control Panel Option

The optional releasing control panel integrated in the FireFlex® DUAL cabinet is a Notifier® model NFS-320. This panel includes two Class A or B, conventional detection zones; four Class B, supervisory zones and four Class A or B, programmable output circuits.

Programming of the control panel is done by FireFlex® Systems. The panel uses conventional devices and is password protected. The panel is compatible with many types of fire alarm & supervisory devices such as linear heat detectors, spot-type heat and smoke detectors, water flow and release indicators, low and high air pressure switches, manual pull stations and abort switches.

The control panel also includes an alphanumeric display with 2 lines of 40 characters describing all the system conditions, as well as a set of red and yellow LED lamps individually indicating the alarm and trouble conditions of the system. Easy to operate control buttons are also provided to activate and operate the system’s various functions.

Using the best technology

The SEVO™ system is UL/ULC Listed and FM Approved. All systems are designed as per the NFPA 2001 standard and in compliance with the limitations and instructions found in the manufacturer’s design manual.

SEVO™ 1230 FORCE500™ Technology

The FIREFLEX® DUAL system uses SEVO™ 1230 FORCE500™ cylinders pressurized at 500 psi and designed for a high volume discharge rate in order to meet the rapid discharge requirements specified in the NFPA 2001 standard. Discharge valves are of brass construction and are designed as per the pressure differential concept. They are also provided with an integrated pressure safety device, a pressure indicating gauge and an electric actuator.

The SEVO™ system is UL/ULC Listed and FM Approved. All systems are designed as per the NFPA 2001 standard and in compliance with the limitations and instructions found in the manufacturer’s design manual. All cylinders are factory-filled with the extinguishing agent and then pressurized with nitrogen allowing maximum flexibility at the time of installation. They are fabricated, tested and stamped according to D.O.T. 4BA500 or 4BW500 or TC specifications depending on their size and capacity.

FireFlex® DUAL CABINET CYLINDER CAPACITY

| CYLINDER SIZE (LBS) |

||||||

|---|---|---|---|---|---|---|

| CABINET WIDTH (IN.) | 40 | 76 | 164 | 322 | 601 | 850 |

| 36* | 1 | 1 | - | - | - | - |

| 46* | - | - | 1 | 1 | 1 | - |

| 52 | - | - | - | - | - | 1 |

Note : 24", 36" and 46" cabinets are available with seismic option.

Why trust the FireFlex team and its systems?

Our cutting-edge systems are an alliance between research, development, quality & durability.

BECAUSE WE ARE INDUSTRY PIONEERS

Since its inception in 1991, FIREFLEX SYSTEMS has been designing and manufacturing state-of-the-art innovative integrated fire protection systems that set the benchmark in the market.

FOR THE WIDEST SELECTION AVAILABLE ON THE MARKET

FIREFLEX SYSTEMS offers the widest selection of integrated systems on the market. Regardless of the hazard to be protected, FIREFLEX is able to offer the best available technology with the widest range of options to suit all needs.

FOR OUR QUALITY CONTROL

FIREFLEX SYSTEMS' commitment, year after year, to quality and continuous improvement has resulted in achieving and maintaining its ISO 9001 quality certification. Its modern facilities are geared towards producing a high-volume of quality integrated systems in a factory-controlled setting.

FOR OUR TECHNICAL SUPPORT

Whether it is through exhibits, conferences, lunch & learn presentations, technical seminars, Webinars or one-on-one technical discussions, FIREFLEX's technical sales representatives draw on their in-depth knowledge and expertise to provide a level of technical support that meets or exceeds customer expectations.

FOR OUR CUSTOMER SERVICE

Our customer service department is readily available to address any product related service call, replacement part or general operation and maintenance questions that may arise. All our integrated product lines possess a serial number which is entered into our database. This enables FIREFLEX to record and track service calls, replacement parts, or any system modifications that have been reported on individual units.

FOR OUR INNOVATIVE PRODUCTS

Actively involved with research and development, FIREFLEX embarked on a new endeavor to better serve the fire protection practitioner in addressing challenging fire protection scenarios that evolve in modern life.

Protects mission-critical facilities

Environmental-friendly Extinguishing Agent

The FireFlex® DUAL system uses FK-5-1-12 Fire Protection Fluid. This clean extinguishing agent is based on sustainable technology and is the only chemical agent currently available that not only meets current regulations but also those in the future regulatory framework.

The FireFlex® DUAL integrated systems are thus adapted for use in any mission critical facility requiring a clean extinguishing agent that is not only fast and efficient, but also safe for people and the environment, such as :

- Telecommunication centers

- Server rooms and data storage

- Control rooms

- Art galleries & museums

- Medical treatment centers & laboratories

- Archives

- Emergency diesel generators

APPROVALS

Air Supply for Cabinets

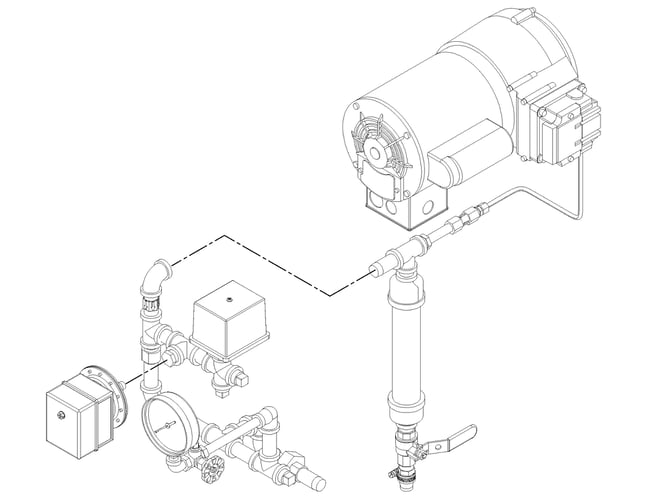

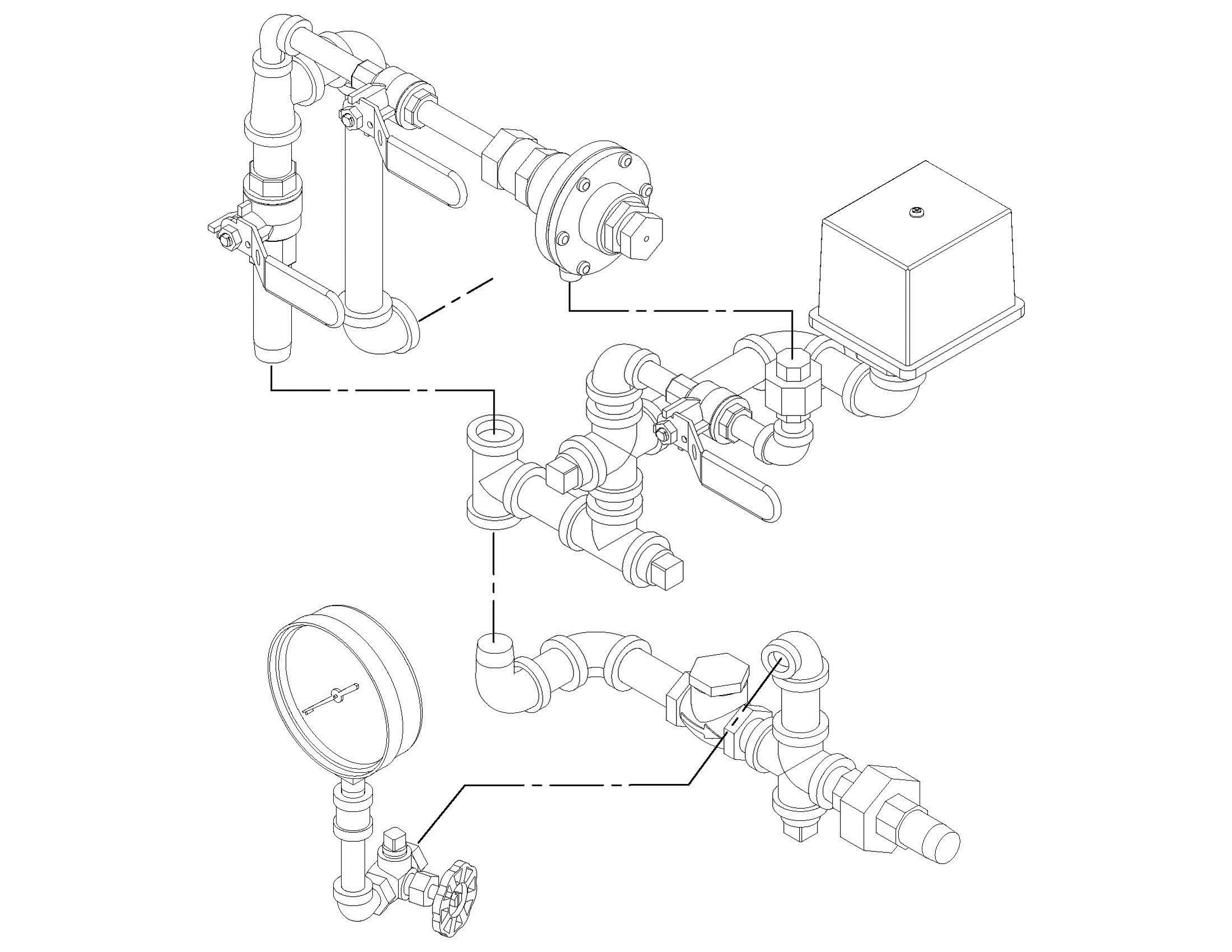

Air supply style “A”: is used to supervise the sprinkler piping network of preaction systems. This option includes an oilless piston-type air compressor with supervisory trim integrated in the FireFlex® DUAL cabinet and factory piped to the system riser.

AIR SUPPLY STYLE "A"

MORE AIR SUPPLY OPTIONS

Air supply style “B”: is provided with an air pressure maintenance device factory mounted and adjusted in the FireFlex® DUAL cabinet and piped to the air inlet port of the unit.

Two styles of air supplies are available for the FIREFLEX® DUAL units depending on needs or configurations. These air supplies are factory assembled and pressure tested.

Air supply style “B”

Used to supervise the sprinkler piping network of preaction systems when the external air supply (by tank-mounted air compressor, plant air or dry nitrogen cylinders) is provided by others.

Note: The air supply must be restricted to ensure that it cannot replace

air as fast as it escapes when a releasing device or sprinkler operates.

SEVO Discharge Nozzles

The SEVO™ discharge nozzles are designed to provide a complete and rapid vaporization of the FK-5-1-12 Fire Protection fluid as well as properly distribute the agent within the protected space. Standard nozzles are made of aluminum and are available in various sizes, including ½”, 1”, 1½”, 2” and 2½”. Both 180º and 360º models cover a maximum area of 32’ x 32’ with a maximum height of 16’- 4” (FM) or 14’-0’’ (UL/ULC).

SEVO™ DISCHARGE NOZZLES

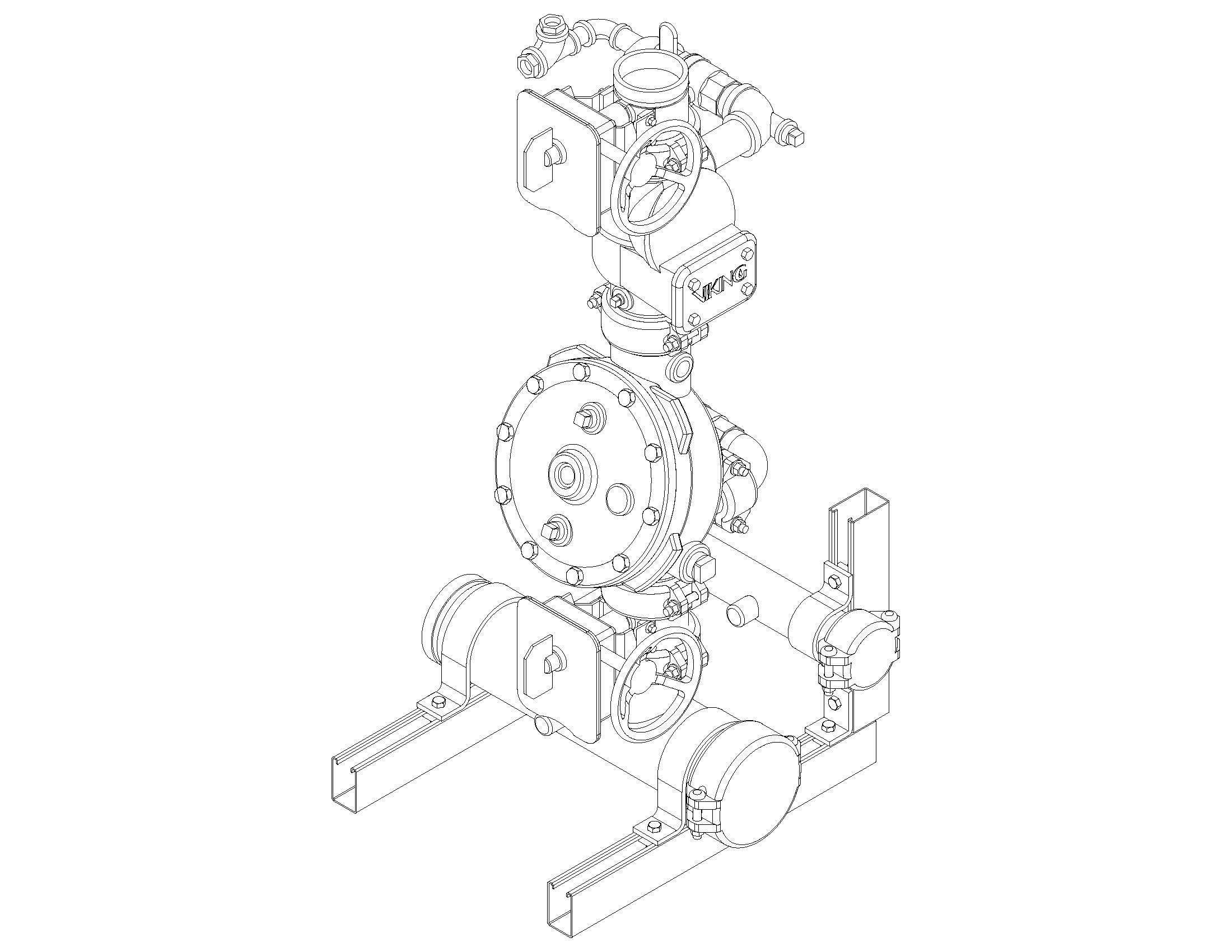

PREACTION AUTOMATIC SPRINKLER SYSTEM

The FireFlex® DUAL system integrates a Viking Preaction sprinkler system with the Model F1 Straight Through Deluge Valve. FireFlex® DUAL systems are provided with an integrated 2”or 3” diameter single or double interlocked preaction system.

The FireFlex® DUAL system uses FK-5-1-12 Fire Protection Fluid combined with a Viking Preaction System. Factory assembly of the FireFlex® DUAL cabinets ensures that all components have been properly integrated. All systems are fully programmed and tested at the factory which facilitates the onsite installation and commissioning process.

Combined Sequence of Operation

The combined preaction-clean agent suppression system is configured to prevent unwanted water discharge in the hazard. The clean agent system is typically activated by using a cross-zoned smoke detection system. When the detection conditions are fulfilled, the pre-discharge delay timer is activated. Once the pre-discharge delay expires, the uses FK-5-1-12 Fire Protection Fluid is released with the single interlocked preaction system, the piping will fill with water and will discharge in the hazard only if the sprinkler heads have opened. With the double interlocked configuration, it is required that both the detection conditions and the loss of system air pressure occur—further to the opening of a sprinkler— for the water to be released into the system piping. Water will then flow through the open sprinklers.

Riser Shut-off Valve Option

The riser shut-off valve option consists of a supervised butterfly valve which allows for a full flow trip test without flooding the system piping and a sight glass located on the main drain for a visual indication of the water flow.

FireFlex® DUAL Certificates

Certifications per type :

- Preaction: cULus, FM

- Deluge: c-UL-us, FM

- Firecycle® III Preaction: c-UL-us, NYC

- Firecycle® III Deluge: c-UL-us, NYC

- Firecycle® III Wet Pipe: c-UL-us, NYC

- SurefireTM Preaction: c-UL-us, FM, NYC

- Dry Pipe: FM

- Dry Pipe (HP®): c-UL-us & FM (voir note 1)

- Wet Pipe: c-UL-us & FM (voir note 2)

Talk To An Expert

Whether you want to select, specify, install or maintain our systems, you'll find in this section a range of useful documents related to our integrated systems. For further information, do not hesitate to contact our team of experts.