-

FIRE PROTECTION

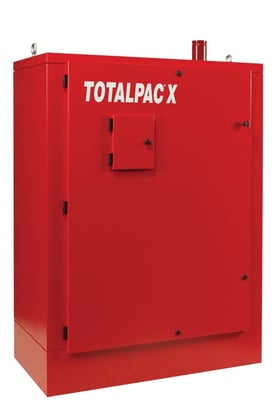

- TOTALPAC® X

Protecting Any Challenging or Unheated Applications

TOTALPAC®X system is designed for indoor/outdoor installations and unheated environments, providing innovative fire protection solutions adapted for challenging or harsh applications.

Benefits of the TOTALPAC® X Units

Designed with user-friendly features, the TOTALPAC® X units are easy to install and maintain.

A compact and recognized solution

- Easy and compact installation

- Wide door for easy access

- NEMA 3 or NEMA 4 construction

- Quarter turn door latches

- Lockable door to protect against tampering

- Lifting lugs provided for safe and easy handling

- Corrosion resistant paint finish

- Water supply connection piped through the bottom center of the unit to avoid freeze-up potential

- Single drain connection

- Serial number for easy reference

The Cabinet

Factory assembly of the TOTALPAC® X cabinets ensures that all components have been carefully integrated. All systems are fully programmed and tested at the factory which facilitates the onsite installation and commissioning process.

The TOTALPAC® X cabinets are of the freestanding type and are made of robust 14 gauge steel with a corrosion resistant fire red paint finish, polyester powder-coated and oven-baked on a phosphate base. Cabinets are also provided with a locked frontal door that is removable without special tools, reducing space requirements for ease of installation and maintenance. Furthermore, the door is provided with a neoprene gasket to reduce vibrations.

Technical details:

- Compact layout saves floor space

- Fully tested and programmed at the factory

- Unique serial number on every unit

- User-friendly owner's manual with every unit

- Simplified operation and maintenance

- Factory built under ISO-9001 conditions

Four (4) Construction NEMA Options

NEMA 3*

Enclosures constructed for either indoor or outdoor use to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and windblown dust); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (rain, sleet, snow); and that will be undamaged by the external formation of ice on the enclosure.

Other options also available :

- NEMA4*

- NEMA 3X*

- NEMA 4X*

Comparison of Specific Non-Hazardous Applications*

|

Provides a Degree of Protection Against |

TYPES OF ENCLOSURE |

|||

|---|---|---|---|---|

| 3 | 3X | 4 | 4X | |

| Incidental contact with the enclosed equipment | ||||

| Rain, snow, and sleet | ||||

| Hose−down and splashing water | ||||

| Corrosive agents | ||||

| Ingress of solid foreign objects (Circulating or settling airborne dust, lint, fibers, and flyings)(b) |

||||

| Ingress of solid foreign objects (Windblown dust, lint, fibers, and flyings)(b) |

||||

a: these enclosures may be ventilated.

b: these fibers and flyings are nonhazardous materials and are not considered class III type ignitable fibers or combustible flyings.

Multiple Models and Available Configurations

Our adaptability, in order to better meet our customers' needs, is our main priority.

Available Configurations

Preaction

- Non-interlocked with pneumatic or electric release

- Single interlocked with pneumatic or electric release

- Double interlocked with pneumatic-pneumatic, electric-pneulectric or electric-pneumatic release

Surefire®

- Failsafe single or double interlocked preaction system

Multicycle

- Firecycle® III single or double interlocked preaction

- Firecycle® III deluge

- Firecycle® III wet

Dry Pipe

- Available in standard 175 psi or HP 250 psi

Wet Pipe

- Available with constant pressure trim, retard chamber or excess pressure pump

Dimensions of the TOTALPAC® X Units

System Selection

|

SYSTEM TYPES |

Types of Enclosure |

|||

|---|---|---|---|---|

| 3 | 3X | 4 | 4X | |

| Wet Pipe | ||||

| Dry Pipe | ||||

| Deluge | ||||

| Preaction, standard single or double interlocked, or Surefire® |

||||

| Firecycle® wet, dry, deluge, preaction single or double interlocked |

||||

Available with air option “B” only

Why trust the FireFlex team and its systems?

Our cutting-edge systems are an alliance between research, development, quality & durability.

BECAUSE WE ARE INDUSTRY PIONEERS

Since its inception in 1991, FIREFLEX SYSTEMS has been designing and manufacturing state-of-the-art innovative integrated fire protection systems that set the benchmark in the market.

FOR THE WIDEST SELECTION AVAILABLE ON THE MARKET

FIREFLEX SYSTEMS offers the widest selection of integrated systems on the market. Regardless of the hazard to be protected, FIREFLEX is able to offer the best available technology with the widest range of options to suit all needs.

FOR OUR QUALITY CONTROL

FIREFLEX SYSTEMS' commitment, year after year, to quality and continuous improvement has resulted in achieving and maintaining its ISO 9001 quality certification. Its modern facilities are geared towards producing a high-volume of quality integrated systems in a factory-controlled setting.

FOR OUR TECHNICAL SUPPORT

Whether it is through exhibits, conferences, lunch & learn presentations, technical seminars, Webinars or one-on-one technical discussions, FIREFLEX's technical sales representatives draw on their in-depth knowledge and expertise to provide a level of technical support that meets or exceeds customer expectations.

FOR OUR CUSTOMER SERVICE

Our customer service department is readily available to address any product related service call, replacement part or general operation and maintenance questions that may arise. All our integrated product lines possess a serial number which is entered into our database. This enables FIREFLEX to record and track service calls, replacement parts, or any system modifications that have been reported on individual units.

FOR OUR INNOVATIVE PRODUCTS

Actively involved with research and development, FIREFLEX embarked on a new endeavor to better serve the fire protection practitioner in addressing challenging fire protection scenarios that evolve in modern life.

Additional Options

Designed with user-friendly features, the TOTALPAC®X units are easy to install and maintain.

Low Temperature Sensor

- The low temperature sensor will close the normally open contact when the temperature drops below 40°F (4.5°C).

- The sensor will automatically reset to its normal state when the temperature rises above 40°F (4.5°C).

Heater Option

Heater option is recommended where ambient temperature can drop below 40°F (4.5°C). The cabinet’s electric heater temperature cut-out point is set at 50°F (10°C). The heater option is equipped with a low temperature sensor that will activate a supervisory signal when temperature drops below 40°±5°F (4.5°±3°C).

Warning: TOTALPAC®X cabinet is rated to provide freeze protection down to a minimum temperature of 14°F (-10°C).

Riser Shut-off Valve Option and more

The riser shut-off valve option consists of a supervised butterfly valve which allows for a full flow trip test without flooding the system’s piping and a sight glass located on the main drain for visual indication of the water flow.

Light Option

- Optional DEL enclosure light is available for all cabinet configurations

- Remote door switch activates the light when the door is opened

- Light option can be ordered in two supply voltage settings:

- 120Vac-60Hz

- 220Vac-50Hz

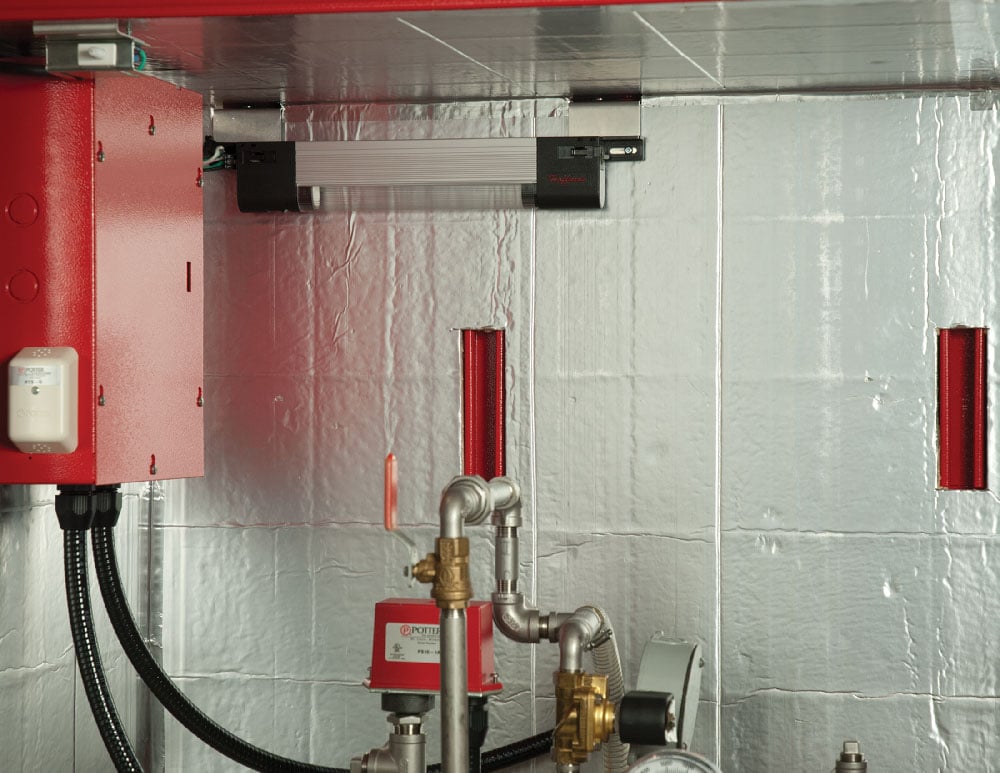

Insulated Enclosure

Insulation is made on foam core 2” thick R13 and have a foil-faced sheathing board

composed of a uniform closed cell polyisocyanurate foam core bonded on each side to a triminate foil facer. Both sides have a foil reflective facer.

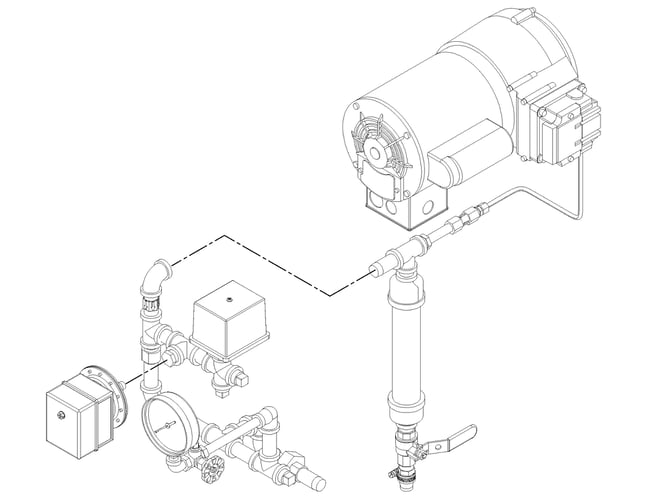

Air Supply for Cabinets

The automatic sprinkler piping is supervised by compressed air from a source installed inside or outside the cabinet. The air supply must be regulated. When the compressor option is selected (air supply style “A”), the motor must be sized to restore normal system air pressure within 30 minutes as per NFPA 13 requirements.

Air Supply Style "A"

More Air Supply Alternatives

Air supply style “B”:

This option is provided with an air pressure maintenance device factory mounted and adjusted in the TOTALPAC®X cabinet and piped to the air inlet port of the unit. Used to supervise the sprinkler piping network of dry or preaction sprinkler systems when the external air supply (by tank-mounted air compressor, plant air or dry nitrogen cylinders) is provided by others.

Note: the air supply must be restricted to ensure that it cannot replace air as fast as it escapes when a releasing device or sprinkler operates.

Air supply style “C”

This option is provided with an air pressure maintenance device factory mounted in the TOTALPAC®X cabinet. Used only for the pilot line of a pneumatically operated system.

Air supply style “D”

This option is provided with an air supervisory switch and shut-off trim. Used for freezer application with external air supply and regulation.

APPROVALS & STANDARD LISTING

Talk To A Fire Protection Expert

Whether you want to select, specify, install or maintain our systems, you'll find in this section a range of useful documents related to our integrated systems. For further information, do not hesitate to contact our team of experts.